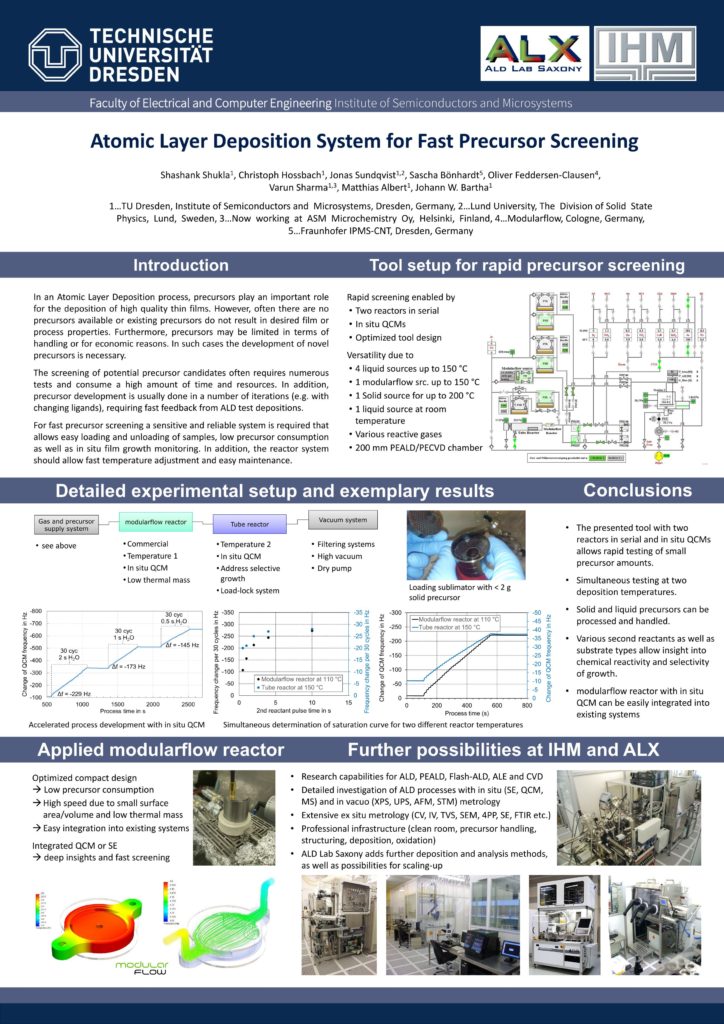

IHM of TU Dresden and Fraunhofer have under the collaboration of “ALD Lab Saxony” for a number of years collaborated with Modularflow in using the Mini ALD Reactor for fast precursor screening. They presented results together in the Poster Session of ALD 2016 some weeks ago (see Poster below). The presented work was part of the Master Thesis research of Shashank Shukla at IHM TU Dresden under Prof. Bartha.

Modularflow has launched the new mini ALD reactor with integrated Quartz Crystal Microbalance (QCM) to be used in R&D for processing small 1 inch coupon based substrates or by using the double sided high sensitivity QCM conduct very fast precursor screening and development.

modularflow mini ALD reactor

- Ultra-compact metal sealed table-top precursor and process screening system

- Up to 4 precursor sources (2 heatable up to 190°C, 2 unheated)

- Double-sided media contact of the QCM with polymer sealed electrical contact surfaces

- Designed for fume cupboard and glove box application (discrete electronic box)

![MiniALD[1]](http://www.ald-lab-saxony.de/wp-content/uploads/2016/08/MiniALD1.jpg)

modularflow mini ALD Dimensions with 3 precursor sources: approx. 420 x 260 x 350 mm

- Operating temperature substrate holder: up to 300° C

- Operating temperature QCM: up to 250° C

- Operating pressure: 0 to 1000 mbar (absolute)

- Maximum substrate size: Ø26 mm x 2 mm

- Crystal sensor: Ø14 mm (metal-ceramic feed through)

ALD-cycle control (PLC based with 3,5‘ touchscreen) with:

- pressure graph of the ALD cycle

- exposure time enhancement with multiple precursor pulses

- carrier gas modulation for enhancement of precursor transport

- Ethernet-connectors (e.g. for HMI remote viewer)

Poster presentation

Further information on the modularflow reactor can be found on BALD Engineering Blog.

![ModularFlow+Reactor[1]](http://www.ald-lab-saxony.de/wp-content/uploads/2016/08/ModularFlowReactor1-300x247.png)